DHC

Quality Assurance

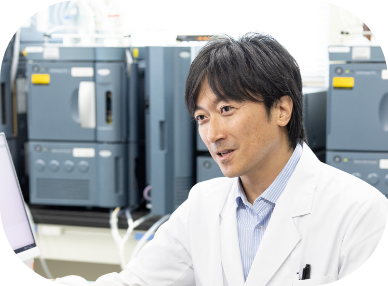

DHC creates products with an emphasis on safety.

The core goal of DHC�fs research and development is to bring happiness to as many people as possible.

DHC Olive Virgin Oil

Manufacturing Process

Learn how DHC Medicated Lip Cream containing DHC Olive Virgin Oil is prepared.

stepO1

Weighing

Preparing and weighing raw materials

The various raw materials used in DHC Medicated Lip Cream are weighed in preparation for subsequent steps. All raw materials are controlled using label bar codes, which clearly indicate dates, times, ingredients, staff responsible, and other information. The system sounds an alarm if any incorrect materials are selected.

stepO2

Bulk production

Mixing materials to prepare the product base

The process of placing raw materials in a mixing machine is known as blending. This takes place under strict temperature controls. All conditions, ranging from the number of rotations to the time at which materials are added, are precisely described in operating manuals. Staff monitor the preparations constantly, looking for foaming or other abnormalities.

stepO3

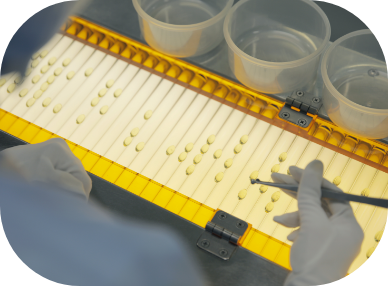

Filling

Filling bulk materials and checking product forms and containers

Cooled, hardened bulk materials are melted and placed in filling machines. Parameters such as temperature and humidity are monitored at each section of the machinery to ensure uniform quality. After filling, products are cooled and formed before being placed in containers.

Staff tighten caps while checking the contents for impurities, defects, or discoloration. In this state, the containers are also checked to make sure they are free of any issues before delivery to the next process.

stepO4

Packing

The final step of production, in which lot numbers are managed to ensure safety

Seals with machine-printed lot numbers are affixed to the underside of containers. At the same time, staff seal the individual boxes, internal packing, and lids and deliver the products, after which lot numbers are printed on individual boxes and lids are security-sealed. At this point, the products are complete.