quality assurance

DHC Quality Assurance

At DHC, the safety of our products is paramount.

The core goal of DHC�fs product development, production,

and sales is to spread happiness to everyone.

- DHC�fs quality

assurance - Quality assurance

organization - Focal points

in cosmetics - Focal points

in supplement - After-sales

service

quality assurance

That�fs why DHC emphasizes quality control as a key responsibility of a manufacturer.

Our Quality Control Office is the heart and soul of DHC product safety,

working daily to deliver reliable supplements to our customers.

Safety initiatives

DHC conducts testing on raw materials before they are delivered to the plant and on finished products before they are shipped out.

We ensure safety through checks conducted by the Quality Management Office and inside product plants at three stages: raw materials, products before packaging in pouches or containers, and final products.

Only products that have fully passed all tests are brought to market.

Raw materials inspection

DHC�fs Quality Management Office rigorously tests fragrance, color, and other properties of raw materials

before they are delivered to the plant.

We also conduct microbial testing for general bacteria, colon bacilli, mold,

and yeast, along with analysis and

testing of key ingredients to make

sure products contain their full complement of beneficial ingredients.

stepO1

Weighing and quantitative testing

Weighing

This test checks capsule measurements and weights. The resulting figures are managed by computer and transmitted to the central system.

Quantitative testing

We confirm that capsules contain the specified volumes of ingredients by dissolving capsule contents in a solvent and measuring them using specialized machinery.

stepO2

Destructive testing

Capsules are placed in pure water and shaken vertically for 20 minutes before checking their state to confirm they will be properly digested after consumption.

stepO3

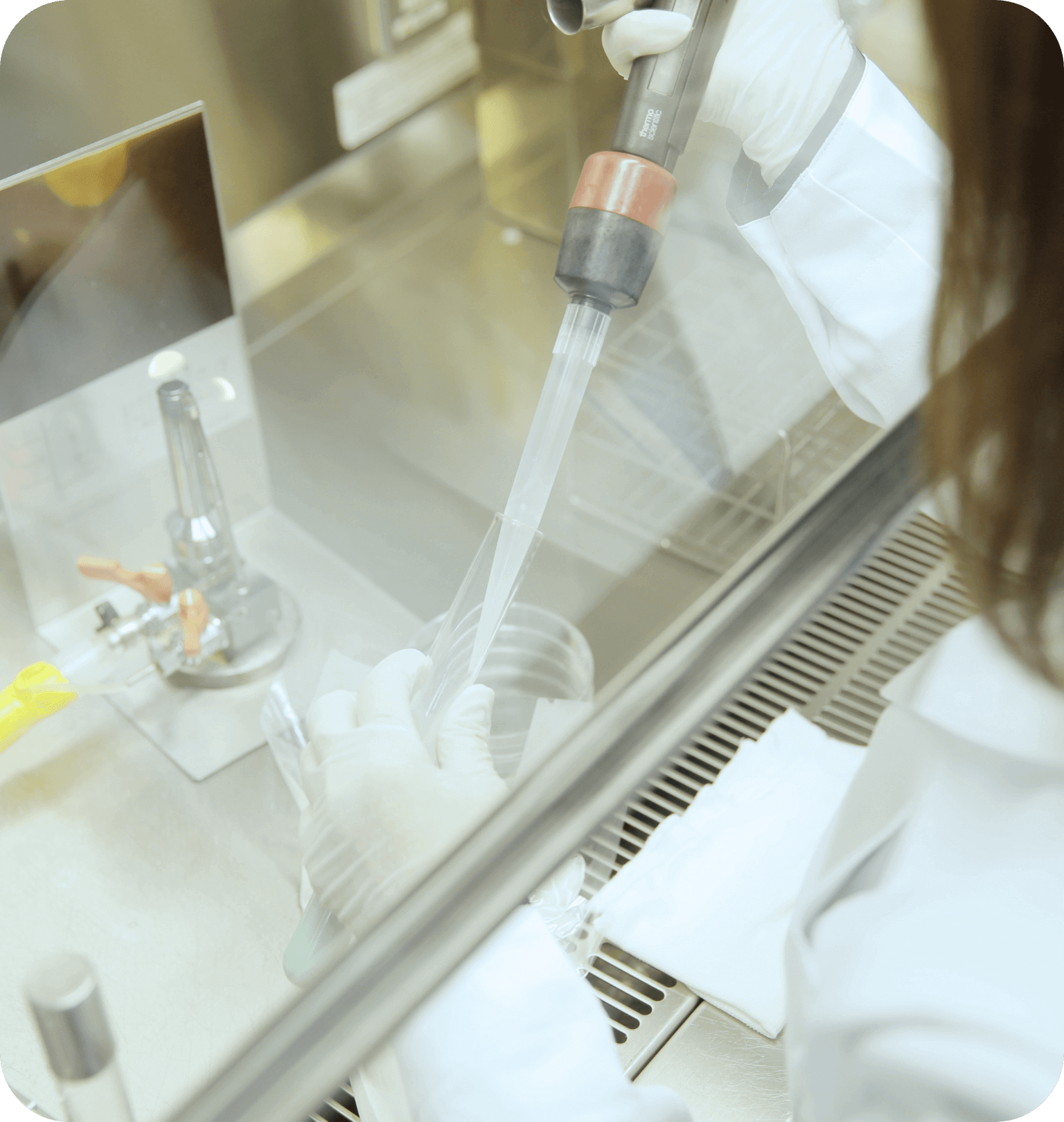

Microbial testing

Products are checked in a clean environment to confirm they are entirely free from harmful microbes. This is normally done three times: on receipt of raw materials, after visual inspection of capsules, and after portioning products into packages.

stepO4

Package specification inspection

We check to confirm that printed best-by dates and lot numbers found on pouches and the numbers of capsules provided are as specified.