quality assurance

DHC Quality Assurance

At DHC, the safety of our products is paramount.

The core goal of DHC�fs product development, production,

and sales is to spread happiness to everyone.

- DHC�fs quality

assurance - Quality assurance

organization - Focal points

in cosmetics - Focal points

in supplement - After-sales

service

quality assurance

That�fs why DHC emphasizes quality control as a key responsibility of a manufacturer.

Our Quality Control Office is the heart and soul of DHC product safety,

working daily to deliver reliable supplements to our customers.

DHC SUPPLEMENT

PRODUCTION PROCESSES

DHC�fs painstaking supplement production process consists of multiple stages, from preparation of raw materials to delivery of final products to customers.

stepO1

Weighing and

mixing capsule

contents

After measuring the total weight of the raw materials, contents are moved from drums to vacuum emulsifiers. Once all raw materials have been added, the resulting mixture is agitated to a uniform consistency. The contents are then passed through a fine filter to a separate tank while checking for impurities or other defects.

stepO2

From capsule

formation to

tumbler drying

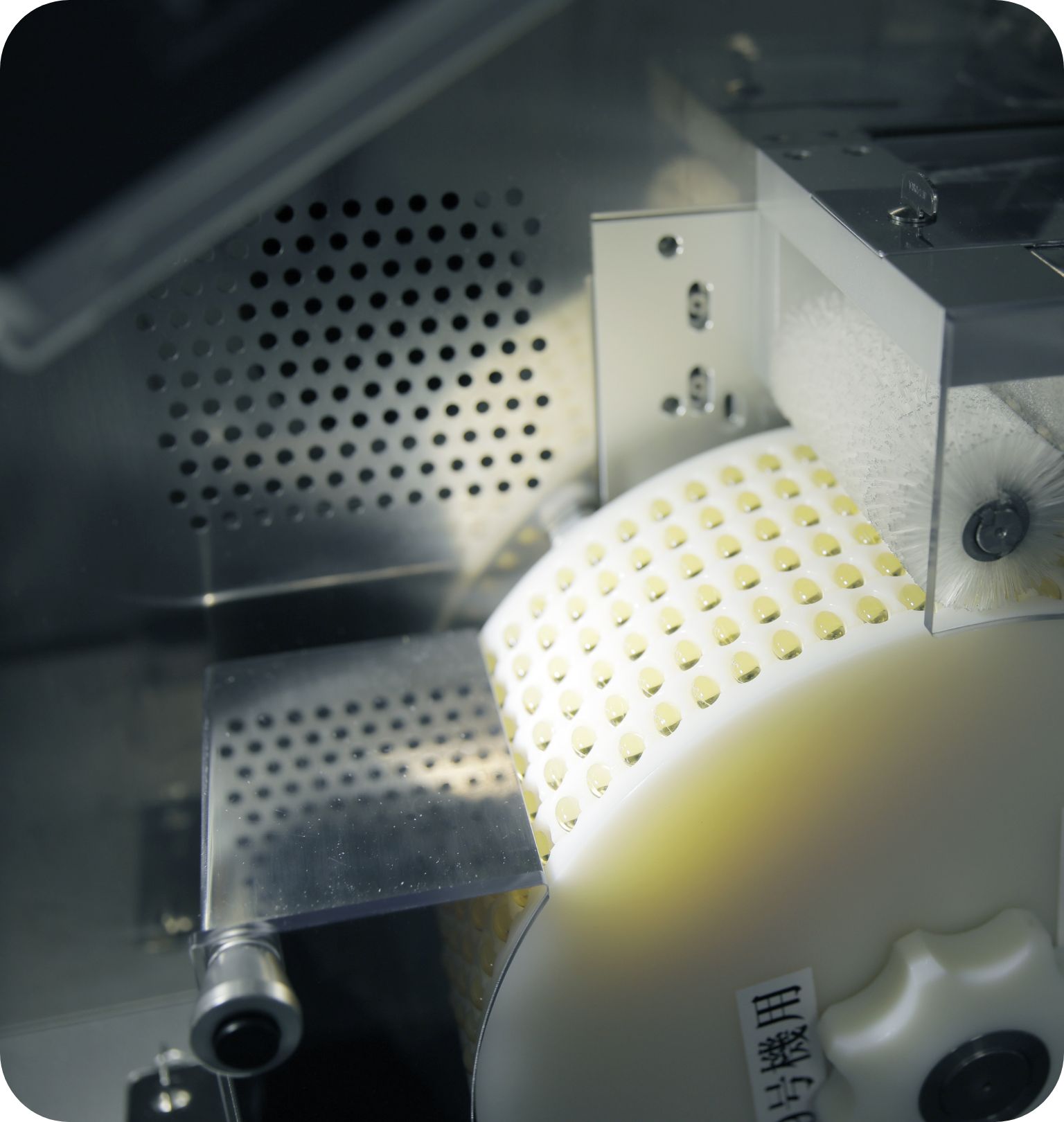

Capsule formation

Supplement capsules are made of gelatin. Two sheets of gelatin are punched into semispherical halves. The specified contents are injected before the two halves are brought together. The machinery operates around the clock, producing 75,000 capsules per hour.

Tumbler drying

Capsules are dried for 24 to 30 hours while exposed to streams of air inside a drying room with a room temperature of about 23��C and humidity of 30% or less.

stepO3

Laser printing

The DHC logo is laser printed on each capsule in a pocket.

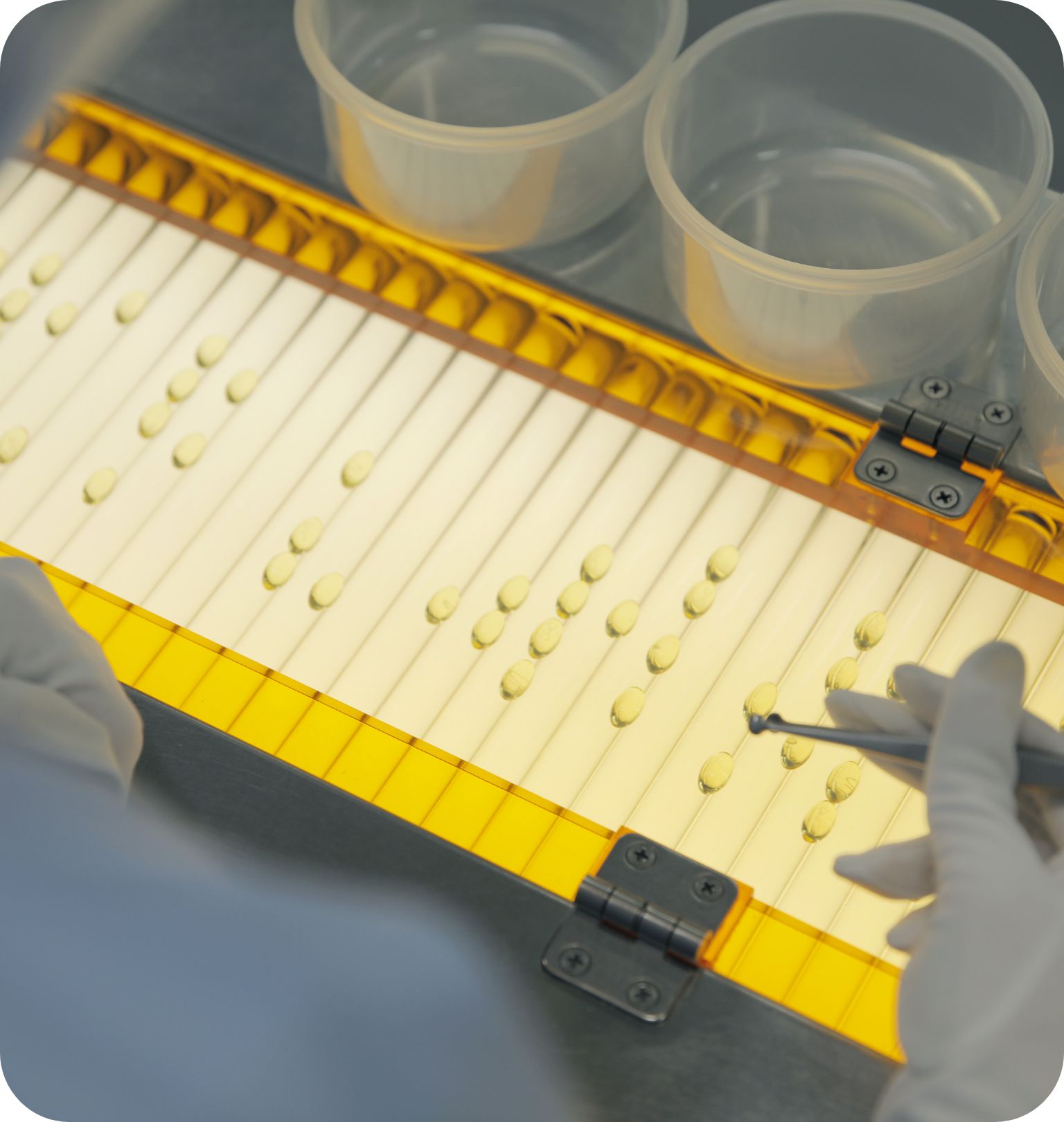

stepO4

Visual capsule

sorting

Capsules are checked visually for scratches, deformation, air bubbles, laser misprinting, and other defects. These duties are handled by staff who are required to pass tests administered every three months. Each staff member is able to check some 50,000 capsules in approximately 15 minutes.