quality assurance

DHC Quality Assurance

At DHC, the safety of our products is paramount.

The core goal of DHC�fs product development, production,

and sales is to spread happiness to everyone.

- DHC�fs quality

assurance - Quality assurance

organization - Focal points

in cosmetics - Focal points

in supplement - After-sales

service

quality assurance

DHC products are developed and manufactured through numerous inspection systems.

Rigorous testing places top priority on safety and provides consumers with peace of mind.

Only products that pass all of these tests are delivered to customers.

Production commitment

We manage production through various methods, including ensuring traceability by maintaining gaps in the lot numbers between different production lines for the same product.

stepO1

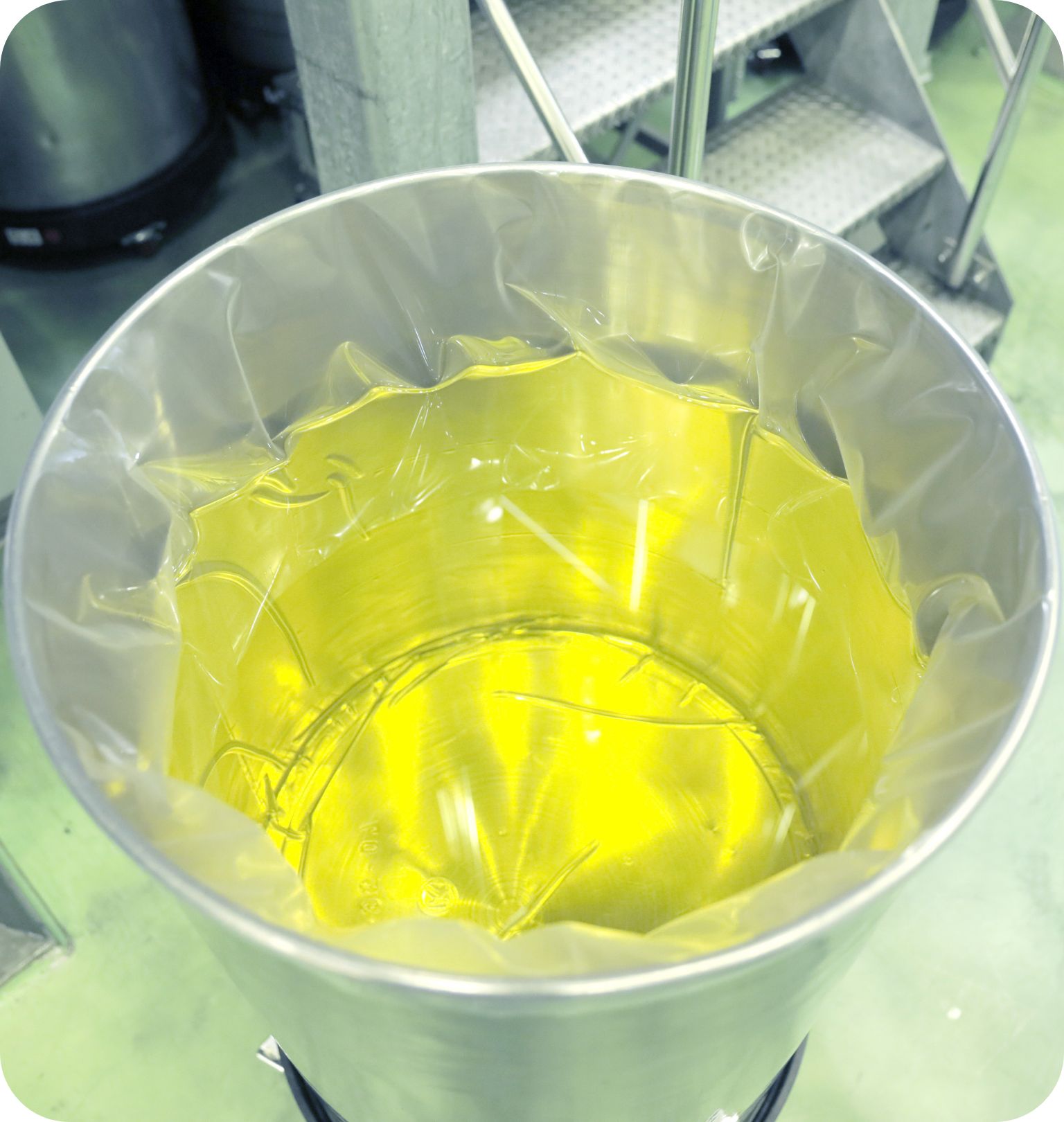

Filtration, refining

Olive oil imported from Spain is refined to satisfy strict standards before being mesh-filtered to eliminate impurities.

stepO2

Measurement, storage

Refined olive oil is transferred to containers for measurement and then stored in a bulk storeroom controlled at 28��C or below.

stepO3

Filling

Bottles are filled with bulk olive oil while avoiding exposure to outside air. The bottles used are kept clean using air cleaners to vacuum out any dust, after which bottle pumps are visually checked for any irregularities and then attached.

Next, the pumps are sealed and protective caps attached. Staff constantly check closely for any scratches or dirt on the bottles and caps.

stepO4

Packing

During the process of machine-printing lot numbers on the bottom of bottles, we use weight checkers to check for accuracy. All of the following steps are done by hand: box assembly, document insertion, placing glass bottles in protective frames, and sealing the boxes. Only then is the product complete and ready for shipping.

Every day, we produce 12,500 bottles of DHC Olive Virgin Oil.